What is a pump coupling?

May 07, 2025

Leave a message

What is a pump coupling?:

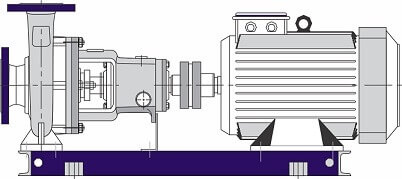

Pump coupling is used to connect shafts in different mechanisms. It mainly transmits the rotational power of the motor to the mechanical parts of the water pump through rotation to achieve torque transmission. Under the action of high-speed power, the pump coupling has the function of buffering and reducing the vibration. Pump coupling has a better service life and a working efficiency guarantee.

Couplings are usually aligned by laser, but can also be aligned with rulers and feeler gauges. Couplings must be aligned within a specific tolerance range, because any misalignment will cause premature failure of rotating parts due to additional stress on the centered parts.

Classification of pump couplings:

There are many types of pump couplings, which can be divided into the following types according to the relative position and position change of the two connected shafts:

Fixed couplings : These are mainly used in places where two shafts are strictly aligned and no relative displacement occurs during operation. The structure is generally simple and easy to manufacture, and the instantaneous speed of the two shafts is the same. There are mainly flange centrifugal pump couplings, sleeve centrifugal pump couplings, jacket centrifugal pump couplings, etc.

Mobile couplings: Mainly used in places where the two axes are tilted or have relative displacement during work. According to the way of compensating displacement, they can be divided into rigid movable centrifugal pump couplings and elastic movable centrifugal pump couplings.

(Example of a rigid coupling)

Rigid movable coupling: The coupling uses the dynamic connection between the working parts to compensate for the movement in one or several directions, such as the inlaid pump coupling (allowing axial displacement), the cross-slot pump coupling (used to connect two shafts for parallel displacement or small angular displacement), the universal pump coupling (used in places where the two shafts have large deflection angles or angular position movement during operation), the gear pump coupling (allowing comprehensive displacement), the chain pump coupling (allowing radial displacement), etc.

The rigid coupling cannot adjust the concentricity of the pump shaft and the motor shaft, so it has high requirements for installation accuracy and is often used for the connection of small water pump units and detachable centrifugal pump units.

(Flexible Coupling Example)

Flexible couplings: Use the elastic deformation of elastic elements to compensate for the deflection and displacement of the two shafts. At the same time, the elastic elements also have buffering and flexural properties. Some couplings have been standardized. When selecting, first select the appropriate type according to the work requirements, then calculate the torque and speed according to the diameter of the shaft, then find the applicable model from the relevant manual, and finally perform necessary verification calculations on some key parts.