Description

Technical Parameters

Product Description

HNYB self-balancing multi-stage centrifugal pump adopts an advanced hydraulic model and is a self-developed high-efficiency and energy-saving product. Since the pump rotor has no wear and axial movement of the balance disc, the alignment of the impeller and the guide vane is always in the best state. Different from other multi-stage pump structures, the efficiency is significantly reduced with the wear of the balance disc and the forward movement of the rotor parts, and there is no leakage of balance water, which reduces the volume loss. Overall, the operating efficiency of the pump is improved, the shaft power is reduced, and the efficiency is 3%-12% higher than that of general multi-stage pumps.

Working principle

Driven by the motor, the shaft rotates to do work on the liquid, increasing its energy, so that the required amount of liquid is continuously delivered from the suction tank through the pump's water inlet section, vertical water outlet, positive impeller, positive guide vane, pump middle section, water outlet section, transition pipe, secondary water inlet section, reverse impeller, reverse guide vane, and water outlet section.

Product Video

Product Parameters

| Customized support | OEM, ODM, OBM |

| Power Source | Diesel engine or electric motor |

| Brand Name | HNYB |

| Structure | Multistage Pump |

| Application | Industrial Boilers, Industrial Utilities, Irrigation and Agriculture, Mining industry, Raw Water Intake |

| Place of Origin | Henan, China |

| Power | 3-1600kw |

| Outlet Size | ≤300mm |

| Flow | 3.7-1350m³/ h |

| Head | 50-1800m |

| Material | Cast iron/ductile iron/cast steel/stainless steel |

Model meaning

Structural features

The D/DY/DG/DF,/MD/MDS-P self-balancing multistage centrifugal pump is supported at both ends, and the housing part is segmented. The pump is connected to the motor through a pin elastic coupling.

The pump rotates clockwise from the drive end.

The structure of the pump is shown in the figure.

Stator part

It is mainly composed of suction section (inlet section), middle section, discharge section (outlet section), guide vane, secondary inlet section, stuffing box (tail cover) and bearing body,which all these parts connected with tension bolts into one unit. At the shaft end, the suction port of the pump is horizontal and right, and the discharge port is vertically upward.

Rotor part

It is mainly composed of shaft, impeller, throttle shaft components, bearings and bushings.

Sealing of the pump

The static joint surface between the pump suction section (inlet section), middle section, discharge section (outlet section), and secondary inlet section is sealed with sealant or molybdenum disulfide.

Throttle seals are used between pump stages.

The shaft seals on both sides of the pump are sealed with soft packing.

A water retaining ring is used to prevent water from entering the bearing.

Bearing

The whole rotor of the pump type is supported by the cylindrical roller bearing "GB/T283-94" at the drive end, and the end is supported by "GB/T292-94" angular contact ball bearing.The bearing is lubricated with CD30 or CD40 mechanical oil into the bearing body to the center of the oil mirror.Because the bearing adopts "GB/T292-94" anqular contact ball bearing, the assembled pump rotor has no axial movement.

Product Features

High efficiency and energy saving: using advanced hydraulic models, independently developing high efficiency and energy saving products; because the pump rotor does not have the wear and axial pulsation of the balance disc, the concentricity of the impeller and the guide vane is always in the best state, and the efficiency will not be significantly reduced as the balance disc wears and the rotor parts move forward like the ordinary multi-stage pump structure; and there is no leakage of balancing water, which reduces the volume loss, improves the overall operation efficiency of the pump, reduces the shaft power, and is 3%-12% higher than the efficiency of ordinary multi-stage pumps on average.

New structure: with symmetrically arranged impeller rotor parts, the axial forces generated by the symmetrical impellers at all levels offset each other, and the automatic balance of the huge axial thrust in the pump cavity can be achieved without the use of a balance disc structure, breaking through the traditional structure of multi-stage pumps.

Good cavitation performance and long service life: optimized hydraulic and structural design, precise casting, reliable corrosion-resistant materials, some models of pumps use double suction structure for the first-stage impeller, so that the pump has good anti-cavitation performance, stable operation of the whole machine, low noise and long service life.

Structural features

DP series pumps are used to transport clear water or liquids with physical and chemical properties similar to clear water without solid particles and with a temperature below 80°C.

DYP series pumps are used to transport oil and petroleum products that do not contain solid particles.whose temperature is between -20 and 105°C, and whose viscosity is less than 120cSt.

DGP series pumps are used to transport hot water, oil or abrasive-containing media with a temperature of ≤210°C, which is mainly reflected in the vertical inlet direction of the pump.

DFP series pumps can be used for mine drainage, mainly for conveying mine water and other corrosive liquids that do not contain particles and whose temperature is -20~104°C

MDP/MDSP series pumps can be used for mine drainage, mainly pumping neutral mine water anaother similar sewage with a solid particle content ≤1.5%, a particle diameter ≤1.3mm, and a temperature of -20 ~ 104°C.The user can select the pump material, sealing form, pump structure, and motor capacity according to the characteristics of the conveying medium and on-site use conditions.

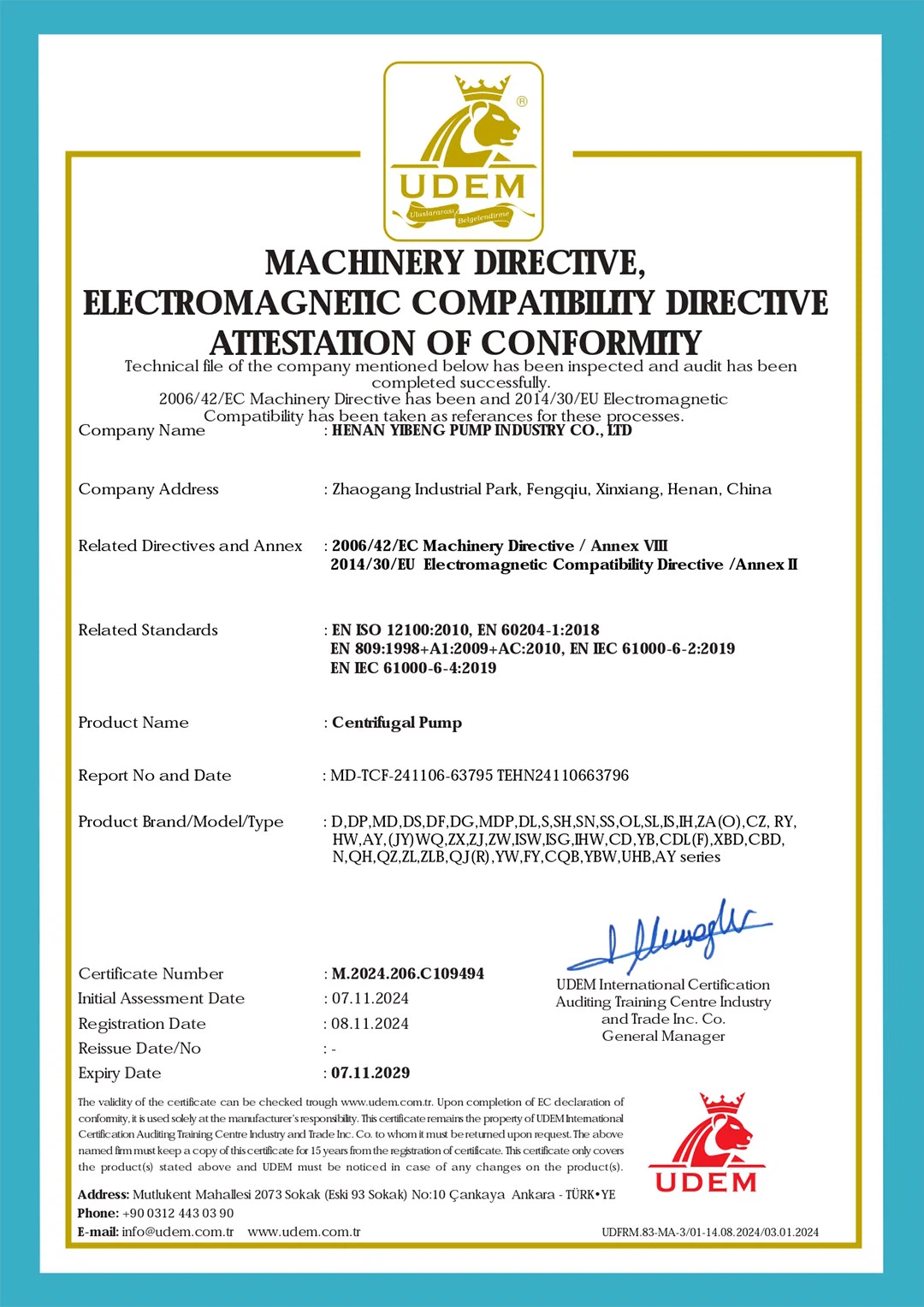

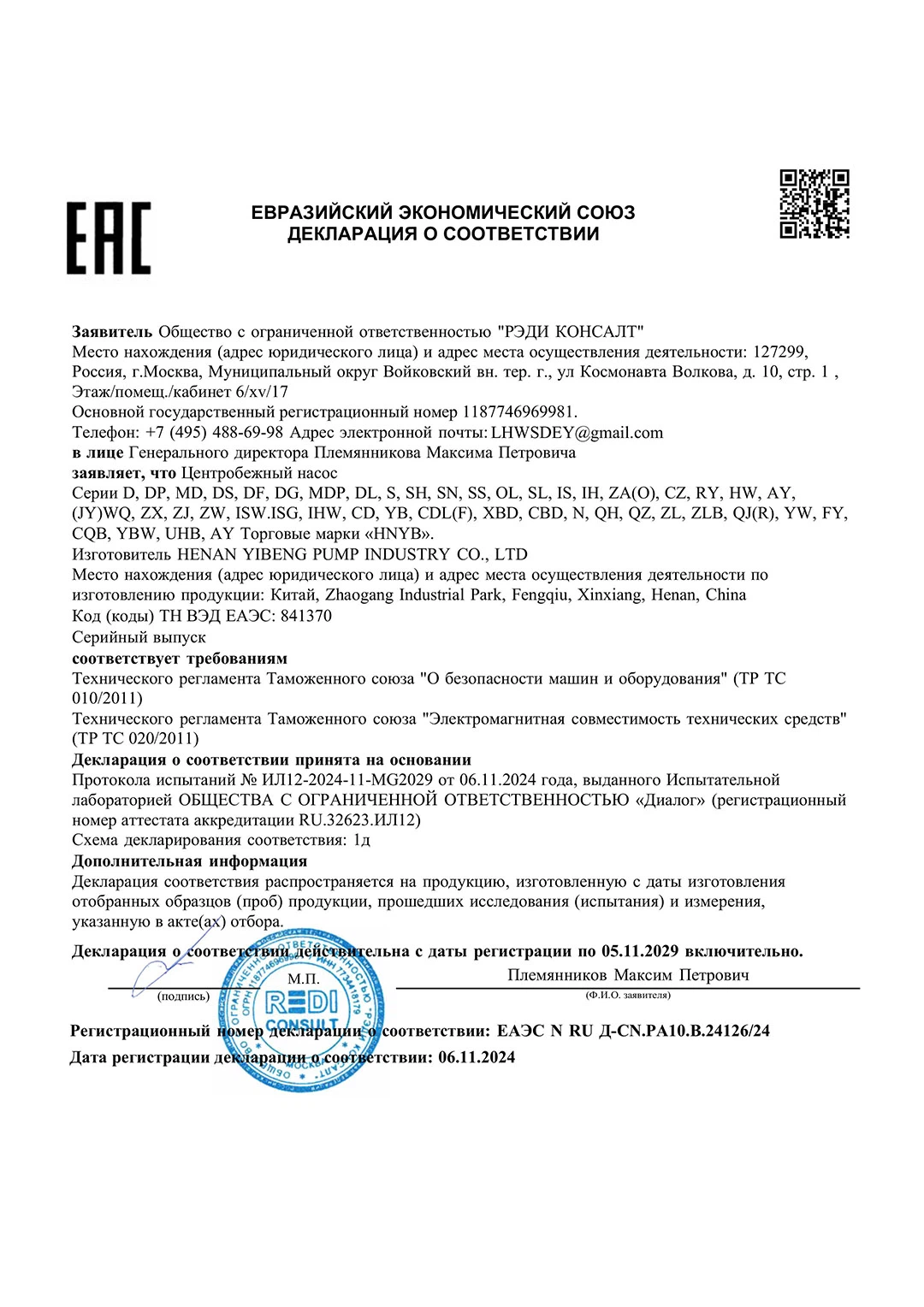

Product Certification

ISO 9001

ISO14001

ISO45001

CE Product Certification

EAC Product Certification

Verified Supplier

Our address

Zhaogang Industrial Park, Fengqiu, Xinxiang, Henan, China

WhatsApp Number

+86 158 3619 1545

sales@hnybpumps.com

FAQ

Q: ARE YOU A MANUFACTORY OR TRADING COMPANY?

A: We are water pump manufactory with more than 30 years production experience.

Q: CAN YOU DO OEM BRAND?

A: Yes, welcome.

Q: WHAT IS THE DELIVERY TIME?

A: 7-10 days according to customer quantities.

Q: WHAT'S YOUR MOQ?

Q: WHAT IS THE PRICE OF THE PRODUCT?

Q: WHAT'S YOUR PAYMENT TERMS?

Q: WHAT CERTIFICATES DO YOU HAVE?

Hot Tags: self-balancing multistage centrifugal pump, China self-balancing multistage centrifugal pump manufacturers

Performance Data

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Efficiency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 6 - 25P |

3 |

3.75 6.3 7.5 |

80.07 75 70.35 |

2950 |

36 47.5 49.5 |

2.48 3.06 3.28 |

5.5 |

2.2 2.8 3.2 |

|

4 |

106.8 100 93.8 |

3.30 4.08 4.37 |

7.5 |

|||||

|

5 |

133.5 125 117.3 |

4.13 5.1 1 5.47 |

7.5 |

|||||

|

6 |

160.1 1 50 140.7 |

|

11 |

|||||

|

7 |

186.3 175 164.2 |

5.78 7.15 7.65 |

11 |

|||||

|

8 |

213.5 200 187.6 |

6.61 8.17 8.75 |

15 |

|||||

|

9 |

240.2 225 211 .1 |

7.43 9.19 9.84 |

15 |

|||||

|

10 |

266.9 250 234.5 |

8.26 1 0.21 10.94 |

18.5 |

|||||

|

11 |

293.6 275 258 |

9.09 11.23 12.03 |

18.5 |

|||||

|

12 |

320.3 300 281 .4 |

9.91 12.25 13.12 |

18.5 |

|||||

specifications

|

Model |

stage S |

Flow Q (m3/h) |

Head H

|

speed (r/min) |

Efficiency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 6 - 50P |

3 |

3.75 6.3 7.5 |

156 150 144 |

2950 |

28 30 29 |

5.56 8.58 10.1 |

15 |

2.5 3.0 3.5 |

|

4 |

208 200 192 |

7.58 11.4 13.5 |

18.5 |

|||||

|

5 |

260 250 240 |

|

22 |

|||||

|

|

312 300 288 |

|

30 |

|||||

|

7 |

364 350 336 |

13.3 20.0 23.7 |

|

|||||

|

8 |

416 400 384 |

|

37 |

|||||

|

9 |

468 450 432 |

17.1 25.7 30.4 |

37 |

|||||

|

10 |

520 500 480 |

19.0 28.6 33.8 |

45 |

|||||

|

11 |

572 550 528 |

20.8 31.4 37.2 |

45 |

|||||

|

12 |

624 600

576 |

22.7 34.3 40.6

|

55 |

|||||

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Efficiency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 6 - 80P |

3 |

3.75 6.3 7.5 |

249 240 225 |

2950 |

32 36 35 |

7.95 11 .4 13.14 |

15 |

2.8 3.2 3.5 |

|

4 |

332 320 300 |

10.6 15.26 17.52 |

22 |

|||||

|

5 |

41 2 400 380 |

13.16 19.08 22.19 |

30 |

|||||

|

|

492 480 460 |

1 5.71 22.89 26.86 |

37 |

|||||

|

7 |

572 560 540 |

18.27 26.71 31.53 |

45 |

|||||

|

8 |

652 640 600 |

20.82 30.52 35.04 |

45 |

|||||

|

9 |

732 720 680 |

23.38 34.33 39.7 |

55 |

|||||

|

10 |

812 800 760 |

25.93 38.15 44.37 |

55 |

|||||

|

11 |

892 880 840 |

28.48 41 .97 49.05 |

75 |

|||||

|

12 |

982 960 920 |

31 .35 45.78 53.72 |

75 |

|||||

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Efficiency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 12-25P |

3 |

7.5 12.5 1 5.0 |

81 .3 75 68.3 |

2950 |

43.3 52.1 52.6 |

3.83 4.90 5.30 |

7.5 |

2.0 2.8 3.5 |

|

4 |

108.4 100 91 |

5.11 6.53 7.07 |

11 |

|||||

|

5 |

135.6 125 113.8 |

6.40 8.17 8.84 |

11 |

|||||

| 6 |

162.7 150 136.6 |

7.67 9.80 10.61 |

15 |

|||||

|

7 |

189.8 175 159.3 |

8.95 11 .43 12.37 |

15 |

|||||

|

8 |

21 6.9 200 182.1 |

10.23 13.07 14.14 |

18.5 |

|||||

|

9 |

244.0 225 204.8 |

11.51 14.70 1 5.91 |

18.5 |

|||||

|

10 |

271.1 250 227.6 |

12.79 16.33 17.68 |

22 |

|||||

|

11 |

298.2 275 250.4 |

14.07 17.97 19.45 |

22 |

|||||

|

12 |

325.3 300 273.1 |

15.35 19.60 21 .21 |

30 | |||||

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 12-50P |

3 |

|

1 58.8

142.7 |

|

30.6 42.5 44.6 |

12.01 13.07 |

|

2.2 3.2 4.0 |

|

4 |

21 1 .7

1 90.3 |

1 1 .87 1 6.02 17.43 |

22 |

|||||

|

5 |

264.6 250 237.9 |

14.84 20.02 21 .79 |

|

|||||

|

|

317.5

285.5 |

17.80 24.03 26.15 |

|

|||||

|

7 |

370.4 350 333.1 |

20.77 28.03 30.51 |

37 |

|||||

|

8 |

423.4

380.6 |

23.74 32.04 34.86 |

45 |

|||||

|

|

476.3 450 428.2 |

26.70 36.04 39.22 |

45 |

|||||

|

|

529.2

475.8 |

29.67 40.05 43.58 |

55 |

|||||

|

|

582.1 550 523.4 |

32.64 44.05 47.94 |

55 |

|||||

|

|

635 600 571 |

35.60 48.06 52.30 |

75 |

|||||

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 12-80P |

3 |

7.5 12.5 15.0 |

249 240 225 |

|

38 40 37 |

|

|

2.4 2.9 4.6 |

|

4 |

332 320 300 |

17.86 27.25 33.14 |

45 |

|||||

|

5 |

412 400 380 |

22.16 34.06 41.98 |

55 |

|||||

|

|

492 480 460 |

26.46 40.86 50.82 |

55 |

|||||

|

7 |

572 560 540 |

30.76 47.60 59.66 |

75 |

|||||

|

8 |

652 640 600 |

35.07 54.50 66.28 |

75 |

|||||

|

|

732 720 680 |

39.37 61 .31 75.12 |

|

|||||

|

|

812 800 760 |

43.67 68.13 83.96 |

|

|||||

|

|

892 800 760 |

47.97 74.94 92.80 |

|

|||||

|

|

982 860 920 |

52.81 73.23 101.64 |

132 |

|||||

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 25-80P |

3 |

15 25 30 |

264 240 228 |

|

47 54 56 |

23.0 30.3 33.3 |

37 |

3.1 3.3 3.8 |

|

4 |

352 320 304 |

30.61 40.37 44.38 |

55 |

|||||

|

5 |

440 400 380 |

38.24 50.43 55.43 |

75 |

|||||

|

|

528 480 456 |

45.89 60.51 66.52 |

|

|||||

|

7 |

616 560 532 |

53.53 70.60 77.61 |

|

|||||

|

8 |

704 640 532 |

61.18 80.69 88.70 |

|

|||||

|

|

792 720 684 |

68.83 90.77 99.78 |

132 |

|||||

|

|

880 800 760 |

76.48 100.86 110.87 |

132 |

|||||

|

|

928 880 818 |

86.30 110.72 120.36 |

|

|||||

|

|

1013 960 893 |

96.15 121.02 138.9 |

|

|||||

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Efficiency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 46-30P |

3 |

30 46 55 |

107.3 90 76.2 |

|

|

14.61 16.88 18.26 |

22 |

2.4 2.8 3.2 |

|

4 |

143 120 101 .6 |

19.47 22.50 24.35 |

|

|||||

|

5 |

178.8 150 127 |

24.34 28.13 30.44 |

37 |

|||||

|

|

214.5 180 152.4 |

29.21 33.76 36.52 |

45 |

|||||

|

7 |

250.3 210 177.8 |

34.08 39.38 42.61 |

45 |

|||||

|

8 |

286 240 203.2 |

38.94 45.01 48.70 |

55 |

|||||

|

|

321 .8 270 228.6 |

43.82 50.63 54.78 |

75 |

|||||

|

|

357.5 300 254 |

48.68 56.26 60.87 |

75 |

|||||

|

|

393.25 330 279.4 |

44.25 61.89 66.96 |

75 |

|||||

|

|

429 360 304.8 |

58.42 67.51 73.04 |

|

|||||

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 46-50P |

3 |

30 46 55 |

164.7 150 138.3 |

|

|

25.10 30.21 32.12 |

37 |

2.4 3.0 3.8 |

|

4 |

219.6 200 184.4 |

33.47 40.28 42.82 |

55 |

|||||

|

5 |

274.5 250 230.5 |

41 .84 50.35 53.53 |

75 |

|||||

|

|

329.4

276.6 |

50.21 60.42 64.23 |

75 |

|||||

|

7 |

384.3 350 322.7 |

58.58 68.09 70.50 |

|

|||||

|

8 |

439.2 400 368.8 |

66.94 80.56 85.64 |

|

|||||

|

|

494.1 450 414.9 |

75.31 90.63 96.35 |

|

|||||

|

|

549 500 461 |

83.68 100.70 107.05 |

132 |

|||||

|

|

603.9 550 507.1 |

92.05 110.77 1 17.76 |

132 |

|||||

|

|

658.8 600 553.2 |

100.42 1 20.84 128.46 |

|

|||||

|

Model |

stage S |

Flow Q (m3 /h) |

Head H (m) |

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 46-80P |

3 |

27 46 54 |

264 240 228 |

|

|

|

55 |

3.9 4.2 5.5 |

|

4 |

352 320 304 |

43.90 62.68 68.82 |

|

|||||

|

5 |

440 400 380 |

54.83 78.29 85.97 |

|

|||||

|

|

528 480 456 |

65.80 98.95 103.1 6 |

132 |

|||||

|

7 |

616 560 532 |

76.76 109.61 120.36 |

|

|||||

|

8 |

704 640 608 |

87.73 125.27 137.55 |

185 |

|||||

|

|

792 720 684 |

98.70 140.93 1 54.75 |

|

|||||

|

|

880 800 760 |

109.67 156.59 1 71 .94 |

220 |

|||||

|

|

968 880 836 |

127.1 8 172.36 189.25 |

250 |

|||||

|

|

|

131 .69 188.03 206.66 |

250 |

|||||

|

Model |

stage S |

Flow Q (m3 /h) |

Head H (m) |

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 65-80P |

3 |

50 65 75 |

264 240 228 |

|

|

|

75 |

3.9 4.2 5.5 |

|

4 |

352 320 304 |

|

|

|||||

|

5 |

440 400 380 |

100 107.5 1 1 5 |

132 |

|||||

|

|

528 480 456 |

120 129 138 |

|

|||||

|

7 |

616 560 532 |

140 150.5 161 |

|

|||||

|

8 |

704 640 608 |

160 172 184 |

220 |

|||||

|

|

792 720 684 |

180 193.5 207 |

220 |

|||||

|

|

880 800 760 |

200 215 230 |

250 |

|||||

|

|

968 880 836 |

220 236.5 253 |

280 |

|||||

|

|

|

240 258 276 |

315 |

|||||

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 85-45P |

3 |

55 85 100 |

151.5 135 121.8 |

|

|

35.35 44.39 48.99 |

55 |

3.4 3.6 4.1 |

|

4 |

202 180 162.4 |

47.13 59.1 9 65.33 |

75 |

|||||

|

5 |

252.5 225 203 |

58.91 73.98 81.66 |

|

|||||

|

|

303 270 243.6 |

70.69 88.78 97.99 |

|

|||||

|

7 |

353.5 315 284.2 |

82.47 103.57 114.32 |

132 |

|||||

|

8 |

404 360 324.8 |

94.26 118.37 130.65 |

|

|||||

|

|

454.5 405 365.4 |

1 06.04 133.1 7 146.99 |

|

|||||

|

|

510 450 390 |

119.05 148.05 156.97 |

185 |

|||||

|

|

561 495 429 |

130.96 162.86 172.67 |

185 |

|||||

|

|

612 540 468 |

142.86 177.66 188.36 |

|

|||||

|

Model |

stage S |

Flow Q (m3 /h) |

Head H (m) |

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 85-67P |

3 |

55 85 100 |

219 201 186.9 |

|

|

58.47 69.44 74.41 |

|

3.3 3.8 4.2 |

|

4 |

292 268 249.2 |

77.96 92.59 99.22 |

|

|||||

|

5 |

365 335 31 1.5 |

97.45 1 15.74 124.02 |

132 |

|||||

|

|

438 402 373.8 |

1 16.94 138.89 148.83 |

|

|||||

|

7 |

511 469 436.1 |

136.43 162.04 173.63 |

|

|||||

|

8 |

584 536 498.4 |

155.92 185.19 198.44 |

220 |

|||||

|

|

657 603 560.7 |

175.41 208.33 223.24 |

250 |

|||||

|

|

740 670 610 |

187.9 220.0 239.0 |

280 |

|||||

|

|

814 737 671 |

206.4 242.0 262.9 |

315 |

|||||

|

|

888 804 732 |

225.2 264.0 286.8 |

315 |

|||||

|

Model |

stage S |

Flow Q (m3 /h) |

Head H (m) |

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 85-67P |

3 |

55 85 100 |

219 201 186.9 |

|

|

58.47 69.44 74.41 |

|

3.3 3.8 4.2 |

|

4 |

292 268 249.2 |

77.96 92.59 99.22 |

|

|||||

|

5 |

365 335 31 1.5 |

97.45 1 15.74 124.02 |

132 |

|||||

|

|

438 402 373.8 |

1 16.94 138.89 148.83 |

|

|||||

|

7 |

511 469 436.1 |

136.43 162.04 173.63 |

|

|||||

|

8 |

584 536 498.4 |

155.92 185.19 198.44 |

220 |

|||||

|

|

657 603 560.7 |

175.41 208.33 223.24 |

250 |

|||||

|

|

740 670 610 |

187.9 220.0 239.0 |

280 |

|||||

|

|

814 737 671 |

206.4 242.0 262.9 |

315 |

|||||

|

|

888 804 732 |

225.2 264.0 286.8 |

315 |

|||||

|

Mode |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 85-80P |

3 |

51 85 102 |

264 240 228 |

|

|

|

|

3.2 4.5 5.5 |

|

4 |

352 320 304 |

82.86 105.82 118.93 |

|

|||||

|

5 |

440 400 380 |

103.57 132.27 148.66 |

185 |

|||||

|

|

528 480 356 |

124.29 158.73 178.39 |

|

|||||

|

7 |

616 560 532 |

145.00 185.18 208.13 |

250 |

|||||

|

8 |

704 640 608 |

165.72 211.64 237.87 |

280 |

|||||

|

|

792 720 684 |

186.44 238.09 267.60 |

31 5 |

|||||

|

|

880 800 760 |

207.15 264.55 297.33 |

355 |

|||||

|

|

968 880 770 |

228.01 239.8 301.43 |

|

|||||

|

|

1056 960 840 |

248.74 31 7.65 328.84 |

450 |

|||||

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 85-150P |

3 |

51 85 102 |

468 450 429 |

|

53 60 59 |

123 1 74 198 |

220 |

4.8 5.0 5.5 |

|

4 |

624 600 572 |

164 232 264 |

280 |

|||||

|

5 |

780 750 725 |

205 290 330 |

355 |

|||||

|

|

936 900 858 |

246 348 396 |

450 |

|||||

|

7 |

|

287 406 462 |

|

|||||

|

8 |

1248 1200 1 144 |

328 464 528 |

|

|||||

|

|

1404 1350 1287 |

369 522 594 |

|

|||||

|

|

|

410 580 660 |

|

|||||

|

|

1716 1650 1573 |

451 638 726 |

|

|||||

|

|

1872 1800 1716 |

492 696 792 |

|

|||||

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 100 |

3 |

85

|

177

147 |

|

|

61.2 66 72 |

|

|

|

4 |

236 220 196 |

81.6 88 96 |

|

|||||

|

5 |

295 275 245 |

|

132 |

|||||

|

|

354 330 294 |

122.4 132 144 |

|

|||||

|

7 |

41 3 385 343 |

142.8 154 168 |

185 |

|||||

|

8 |

472 440 392 |

163.2 176 192 |

220 |

|||||

|

|

531 495 441 |

183.6 198 216 |

250 |

|||||

|

|

590 550 490 |

204 220 240 |

280 |

|||||

|

|

649 605 439 |

224.4 242 264 |

280 |

|||||

|

|

708 660 588 |

244.8 264 288 |

31 5 |

|||||

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 120 |

3 |

|

165 150 126.9 |

|

72 78 77 |

60.75 62.84 62.83 |

|

3.2

|

|

4 |

220 200 169.2 |

81 83.79 83.77 |

|

|||||

|

5 |

275.5 250 21 1 .5 |

101.26 104.74 104.72 |

132 |

|||||

|

|

330 300 253.8 |

121.51 125.69 125.66 |

|

|||||

|

7 |

385 350 296.1 |

141 .76 146.63 146.61 |

185 |

|||||

|

8 |

440 400 338.4 |

162.01 167.58 167.55 |

|

|||||

|

|

495 450 380.7 |

182.27 188.53 188.50 |

220 |

|||||

|

|

545 500 430 |

200.8 209.61 213.45 |

250 |

|||||

|

|

599.5 550 473 |

220.88 230.57 234.80 |

280 |

|||||

|

|

654 600 516 |

240.96 251.53 256.14 |

280 |

|||||

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 120 |

3 |

|

210 201 183 |

|

|

88.5 94.5 98.1 |

|

3.5 4.7

|

|

4 |

280 268 244 |

1 18 126 130.8 |

|

|||||

|

5 |

350 335 305 |

147.5 157.5 163.5 |

|

|||||

|

|

420 402 366 |

177 189 196.2 |

250 |

|||||

|

7 |

427 |

206.5 220.5 228.9 |

250 |

|||||

|

8 |

560 536 488 |

236 252 261.6 |

315 |

|||||

|

|

630 603 549 |

265.5 283.5 294.3 |

355 |

|||||

|

|

|

295 315 327 |

355 |

|||||

|

|

770 737 671 |

324.5 346.5 359.7 |

|

|||||

|

|

840 804 732 |

354 378 392.4 |

450 |

|||||

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 120 |

3 |

|

264 240 216 |

|

|

|

132 |

4.2 5.0 6.6 |

|

4 |

352 320 288 |

140 152 156 |

185 |

|||||

|

5 |

440 400 360 |

175 190 195 |

220 |

|||||

|

|

528 480 432 |

210 228 234 |

280 |

|||||

|

7 |

616 560 504 |

245 266 273 |

315 |

|||||

|

8 |

704 640 576 |

280 304 312 |

355 |

|||||

|

|

792 720 648 |

315 342 351 |

|

|||||

|

|

880 800 720 |

350 380 390 |

450 |

|||||

|

|

968 880 792 |

385 418 429 |

|

|||||

|

|

1056 960 864 |

420 456 468 |

|

|||||

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD

|

3 |

|

330 300 261 .6 |

|

69.5 73 71 |

137.1 167.1 197.5 |

220 |

4.2 4.5 5.0 |

|

4 |

440 400 348.8 |

182.78 222.83 263.36 |

280 |

|||||

|

5 |

550 500 436 |

228.48 279.79 327.95 |

355 |

|||||

|

|

660 600 523.2 |

274.18 335.75 392.54 |

450 |

|||||

|

7 |

770 700 610.4 |

319.87 391.71 459.13 |

|

|||||

|

8 |

880 800 697.6 |

365.57 447.67 524.72 |

|

|||||

|

|

990 900 784.8 |

41 1 .27 503.63 590.31 |

|

|||||

|

|

1100 1000 872 |

456.96 559.68 655.9 |

|

|||||

|

|

1210 1100 959.2 |

670.63 615.92 721.93 |

|

|||||

|

|

1046.4 |

731.59 671.92 787.56 |

|

|||||

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 150 |

3 |

|

165 150 127.5 |

|

72 75 74 |

74.89 81 .70 84.46 |

|

3.2

|

|

4 |

220 200 170 |

99.85 108.93 1 1 2.61 |

132 |

|||||

|

5 |

275 250 212.5 |

124.82 136.17 140.77 |

|

|||||

|

|

330 300 255 |

149.78 163.40 168.92 |

185 |

|||||

|

7 |

385 350 297.5 |

174.75 190.63 197.07 |

250 |

|||||

|

8 |

440 400 340 |

199.71 217.86 225.23 |

280 |

|||||

|

|

495 450 382.5 |

224.67 245.10 253.38 |

31 5 |

|||||

|

|

550 500 425 |

249.64 272.33 281.53 |

355 |

|||||

|

|

605 550 467.5 |

274.60 299.56 309.68 |

355 |

|||||

|

|

|

299.56 326.80 337.84 |

|

|||||

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 150 |

3 |

|

264 240 228 |

|

65 75 74 |

130.79 151.0 |

185 |

3.2 5.0 6.6 |

|

4 |

352 320 304 |

132.73 174.38 201 .38 |

220 |

|||||

|

5 |

440 400 380 |

165.91 217.98 251 .72 |

280 |

|||||

|

|

528 480 456 |

199.1 0 261 .58 302.07 |

355 |

|||||

|

7 |

616 560 532 |

232.28 329.00 352.41 |

|

|||||

|

8 |

704 640 608 |

265.46 348.77 402.76 |

450 |

|||||

|

|

792 720 684 |

298.64 392.37 453.10 |

|

|||||

|

|

880 800 760 |

331 .83 435.96 503.44 |

|

|||||

|

|

968 880 836 |

365.23 479.56 554.1 3 |

|

|||||

|

|

|

398.44 523.1 6 604.51 |

|

|||||

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD

|

3 |

|

330 300 261 .6 |

|

69.5 73 71 |

137.1 1 67.1 197.5 |

220 |

4.2 4.5 5.0 |

|

4 |

440 400 348.8 |

182.78 222.83 263.36 |

280 |

|||||

|

5 |

550 500 436 |

228.48 279.79 327.95 |

355 |

|||||

|

|

660 600 523.2 |

274.18 335.75 392.54 |

450 |

|||||

|

7 |

770 700 610.4 |

319.87 391.71 459.13 |

|

|||||

|

8 |

880 800 697.6 |

365.57 447.67 524.72 |

|

|||||

|

|

990 900 784.8 |

41 1 .27 503.63 590.31 |

|

|||||

|

|

1 100 1000 872 |

456.96 559.68 655.9 |

|

|||||

|

|

1210 1 100 959.2 |

670.63 615.92 721 .93 |

|

|||||

|

|

1046.4 |

731 .59 671 .92 787.56 |

|

|||||

specifications

|

Model |

stage S |

Flow Q (m3 /h) |

Head H

|

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 800 |

3 |

|

259.5 240 225 |

|

73 80 81 |

653

|

|

7.1 7.5 8.3 |

|

4 |

346 320

|

871

|

|

|||||

|

5 |

432.5

375 |

|

|

|||||

|

|

480 450 |

|

|

|||||

|

7 |

605.5

525 |

1524 1588 |

|

|||||

|

8 |

|

1742

|

|

|||||

|

|

778.5 720 675 |

2042 |

2240 |

|||||

|

|

865

750 |

2178

|

|

|||||

|

|

951.5 880 825 |

|

|

|||||

![]()

specifications

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Efficiency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 850 |

3 |

705 850 935 |

314 300 289 |

|

80 84 85 |

753 816 833 |

|

7.5 7.8 8.5 |

|

4 |

419 400 386 |

|

|

|||||

|

5 |

529 500 483 |

1255 1361 1389 |

|

|||||

|

|

628 600 579 |

|

|

|||||

|

7 |

733 700 676 |

1757 1906 1945 |

2240 |

|||||

|

8 |

837 800 743 |

2008 2178 2223 |

|

|||||

|

|

942 900 836 |

2259 2450 2501 |

|

|||||

![]()

specifications

|

Model |

stage S |

Flow Q (m3 /h) |

Head H (m) |

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD

|

3 |

|

196.5 180 168 |

|

76.2 78 76.4 |

491 .9 565.9 599.2 |

|

7.7 8.1 8.9 |

|

4 |

262 240 224 |

655.81 754.56 798.89 |

|

|||||

|

5 |

327.5 300 280 |

819.76 943.20 998.62 |

|

|||||

|

|

393 360 336 |

983.72 1 131.84 1 198.34 |

|

|||||

|

7 |

458.5 420 392 |

1 147.67 1320.48 1398.06 |

|

|||||

|

8 |

524 480 448 |

131 1 .62 1509.12 1597.79 |

|

|||||

|

|

589.5 540 504 |

1475.57 1 697.76 1797.51 |

|

|||||

|

|

655 600 560 |

1 639.53 1886.40 1997.23 |

2240 |

|||||

|

|

720.5 660 616 |

1803.49 2075.04 2196.96 |

|

|||||

|

|

786 720 672 |

1967.4 2263.7 2396.7 |

|

|||||

![]()

specifications

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Eff icency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD 1 100 |

2 |

|

186 170 157 |

|

72.9 75.5 73.4 |

556.1 683.0 728.5 |

|

5.3 5.6 6.2 |

|

3 |

279 255 235.5 |

834.2 1024.5 1092.8 |

|

|||||

|

4 |

372 340 314 |

11 12.3 1366.0 1457.1 |

|

|||||

|

5 |

465 425 392.5 |

1390.4 1687.2 1821 .3 |

|

|||||

|

|

558 510 471 |

1668.5 2024.6 2185.6 |

2240 |

|||||

|

7 |

651 595 549.5 |

1946.6 2362.1 2549.9 |

|

|||||

![]()

specifications

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Efficiency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

DF/MD

|

2 |

|

|

|

75.9 76 74 |

454.2 514.7 550.1 |

|

4.3 4.5 4.9 |

|

3 |

189 180 174 |

681.3 772.1 825.1 |

|

|||||

|

4 |

252 240 232 |

908.4 1 029.4 1 100.4 |

|

|||||

|

5 |

314 300 290 |

1126.6 1290.0 1408.8 |

|

|||||

|

|

378 360 348 |

1356.3 1548.0 1690.5 |

|

|||||

|

7 |

441 420 406 |

1582.3 1806.0 1972.3 |

2240 |

|||||

|

8 |

504 480 464 |

1 808.4 2064.0 2254.0 |

|

|||||

|

|

567 540 522 |

2034.4 2322.0 2535.8 |

|

|||||

![]()

specifications

|

Model |

stage S |

Flow Q (m3/h) |

Head H (m) |

speed (r/min) |

Efficiency (%) |

power(kw) |

NPS HR

|

|

|

shaft power P |

Motor power M |

|||||||

|

200DF/MD43P |

3 |

185 280 335 |

144 129 1 16.1 |

1480 |

|

102.9 128.2 141.2 |

160 |

3.0 4.7 6.0 |

|

4 |

192 172 154.8 |

137.2 171.0 188.3 |

200 |

|||||

|

5 |

240 21 5 193.5 |

171 .5 213.7 235.4 |

250 |

|||||

|

6 |

288 258 232.2 |

205.8 256.5 282.5 |

315 |

|||||

|

7 |

336 301 270.9 |

240.1 299.2 329.5 |

355 |

|||||

|

8 |

384 344 309.6 |

274.4 342.0 376.6 |

400 |

|||||

|

9 |

432 387 348.3 |

308.7 384.7 423.7 |

450 |

|||||

|

10 |

470 430 380 |

336.08 427.75 462.52 |

500 |

|||||

|

11 |

517 473 41 8 |

369.69 470.53 508.77 |

630 |

|||||

|

12 |

564 516 456 |

403.3 513.30 555.02 |

630 |

|||||

Send Inquiry