Description

Technical Parameters

Product Description

The structure of a single-stage end-suction centrifugal pump is relatively simple. The design principle is based on the action of centrifugal force. The motor drives the impeller to rotate at high speed. Under the action of centrifugal force, the liquid is thrown from the center of the impeller to the outer edge of the impeller, thereby increasing the kinetic energy and pressure of the liquid and realizing the transportation of the liquid. It is suitable for conveying clear water or liquids with physical and chemical properties similar to clear water, and the medium temperature is less than or equal to 80℃.

Products Description

| Customized support | OEM, ODM, OBM |

| Power Source | Diesel engine or electric motor |

| Brand Name | HNYB |

| Structure | Single-stage pump |

| Application | Chemical industry, oil refining, paper making, sugar refining, food, pharmaceuticals, synthesis Fiber and other industries. |

| Place of Origin | Henan, China |

| Power | Selected based on the viscosity and specific gravity of the liquid |

| Outlet Size | ≤500mm |

| Flow | 1.1-1450m³/h |

| Head | 9-80m |

| Material | Cast iron/ductile iron/cast steel/stainless steel, etc. |

Product Video

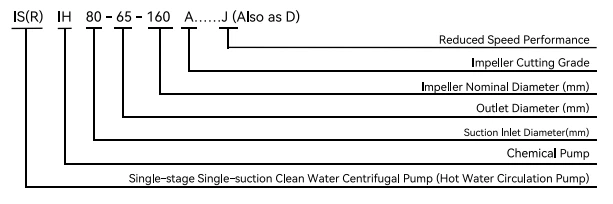

Model meaning

Structural features

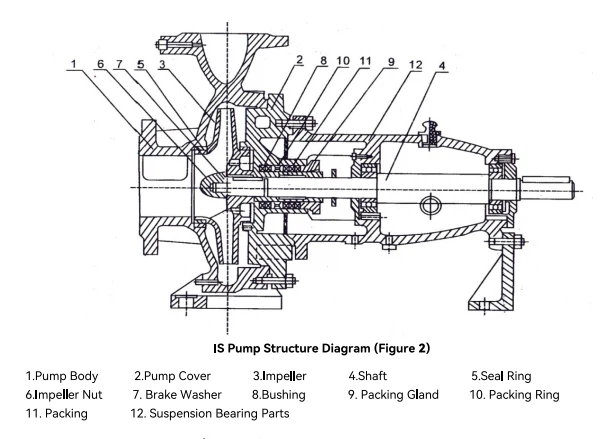

Horizontal installation, horizontal axial suction, discharge port vertically upward. During maintenance, the rotor parts can be pulled out for maintenance without disassembling the inlet and outlet pipes. Depending on the purpose of the shaft seal, a packing seal can be used or a mechanical seal is not required. The materials of various pumps are ordinary cast iron, wear-resistant cast iron, cast steel, cast steel, cast stainless steel, etc. according to different uses. The pump cover is fixed to the middle bracket through a stopper, and then the pump cover is clamped in the middle through the connection between the pump body and the stopper of the middle bracket. The pump body is axially inhaled and radially discharged, and is foot-supported, and can be directly fixed on the base. The suspension part is fixed to the middle bracket through a stopper, and is supported on the base by the suspension bracket. During maintenance, the inlet and outlet connection pipes, pump body, and motor can be removed. Only the middle connection of the extended coupling needs to be removed to remove the rotor parts for maintenance.

Product Features

Simple structure and easy maintenance: The structure of a single-stage end suction centrifugal pump is relatively simple, mainly composed of several parts such as impeller, pump casing, shaft sleeve, mechanical seal, etc., without complex structure or connectors. This makes the single-stage centrifugal pump easy to maintain, easy to operate, and has a low failure rate.

Large flow rate and stable output pressure: The single-stage end suction centrifugal pump has a large flow rate and can stably output a certain pressure. The principle is to suck the liquid from the suction port through the centrifugal action of high speed, and then quickly convert it into kinetic energy through the rotation of the impeller, and finally output high-pressure liquid.

Wide range of applications: Single-stage end suction centrifugal pumps can be used for the transportation of various media, such as water, oil, chemical media, etc. In industrial production, single-stage centrifugal pumps are widely used in liquid transportation, water supply, circulating cooling, oil field water injection, and other fields.

Product Certification

ISO 9001

ISO14001

ISO45001

CE Product Certification

EAC Product Certification

Verified Supplier

Our address

Zhaogang Industrial Park, Fengqiu, Xinxiang, Henan, China

WhatsApp Number

+86 158 3619 1545

sales@hnybpumps.com

Hot Tags: Single-stage end suction centrifugal pump, China Single-stage end suction centrifugal pump manufacturers, Submersible Macerator Pump, Horizontal Multistage Centrifugal Oil Pump, Axially Split Volute Casing Pump, Chemical Resistant Centrifugal Pump, End Suction Horizontal Pump, Centrifugal Vertical Multistage Pump

Product parameters

Previous

No InformationSend Inquiry