Description

Technical Parameters

Products Description

The single-stage double-suction axially split pump is a high-efficiency and energy-saving water pump product suitable for industrial and urban water supply and drainage. The structure is divided into horizontal, single-stage, and horizontal split. It is suitable for conveying other liquids with physical and chemical properties similar to clear water. The medium temperature shall not be higher than 80 degrees Celsius. This type of water pump is widely used in various occasions such as factories, power stations, water conservancy projects, fire protection systems, urban flood control and drainage, etc.

Product Parameter

| Customized support | OEM, ODM, OBM |

| Power Source | Diesel engine or electric motor |

| Brand Name | HNYB |

| Structure | Single stage pump |

| Application | Industrial Boilers, Industrial Utilities, Irrigation and Agriculture, Mining industry, Raw Water Intake |

| Place of Origin | Henan, China |

| Power | 3-1600kw |

| Outlet Size | ≤300mm |

| Flow | 3.7-1350m³/ h |

| Head | 50-1800m |

| Material | Cast iron/ductile iron/cast steel/stainless steel |

Product Video

Structural features

Performance characteristics

The inlet and outlet are both below the axis of the water pump, forming a vertical and horizontal direction with the axis of the water pump. When repairing the water pump, there is no need to disassemble the inlet and outlet pipes and the water pump motor. The rotation direction of the water pump is counterclockwise when viewed from one end of the water pump (the rotation direction of the water pump can also be changed according to user requirements).

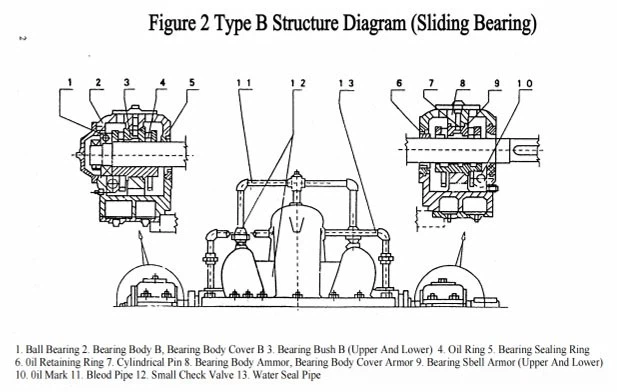

The main parts include the pump body, pump cover, impeller, shaft, double suction sealing ring, sleeve, etc. Except for the pump shaft material which is carbon steel, the other parts are made of cast iron, cast steel, and stainless steel respectively.

The pump body and pump cover form the pump impeller studio. The inlet and outlet flanges of the pump are provided with screw holes for installing vacuum gauges and pressure gauges, and the lower part of the inlet and outlet flanges of the pump is provided with threaded holes for water supply and drainage.

After the static balance test, the impeller is fixed to the pump shaft with a sleeve nut. The axial position can be adjusted through the sleeve nut. The axial force of the impeller is balanced by the symmetrical arrangement of the blades and the water flow on both sides.

The water pump bearing is a radial bearing installed in the bearing body. The bearing seats are installed at both ends of the water pump bearing to fix the bearing operation and lubricate it with butter.

The main function of the double suction seal ring is to reduce the water leakage from the pressure chamber back to the suction chamber.

The water pump is connected to the motor through a coupling, and the motor drives the water pump to rotate. It can also be driven by an internal combustion engine as needed.

The shaft seal is a soft packing seal (a mechanical seal can also be installed according to user needs). In order to prevent air from entering the pump body and to cool and lubricate the sealing cavity, a packing ring is installed between the packings. When the water pump is working, a small amount of high-pressure water flows into the packing cavity through the trapezoidal groove on the opening surface of the pump cover, which acts as a water seal.

Product Certification

ISO 9001

ISO14001

ISO45001

CE Product Certification

EAC Product Certification

Verified Supplier

Our address

Zhaogang Industrial Park, Fengqiu, Xinxiang, Henan, China

WhatsApp Number

+86 158 3619 1545

sales@hnybpumps.com

Hot Tags: single stage double suction axially split case pump, China single stage double suction axially split case pump manufacturers

|

Model |

H ITI |

RPM r,'min |

Power |

'° |

Hs |

Diinttt |

kg |

|||

|

lTi'/h |

I/S |

\iafi f0s'c |

\Í0i0i î0ii |

|||||||

|

10Sh - 19A 250S14A |

320 432 504 |

89 120 140 |

13.3 11 8.6 |

1450 |

15.4 15.8 15.8 |

22 |

78 82 75 |

6 |

224 |

405 |

|

12Sh - 6 300590 |

590 î92 936 |

t64 220 260 |

98 90 82 |

1450 |

2t3 250 279 |

300 |

74 77.5 75 |

5.4 4.5 3.5 |

540 |

847 |

|

12Sh - 6A 300S90A |

576 755 918 |

160 210 255 |

86 78 70 |

1450 |

190 217 246 |

260 |

71 74 71 |

5.5 4.7 3.6 |

510 |

845 |

|

12Sh - 6B 300S90B |

540 720 900 |

150 200 250 |

72 67 57 |

14ß0 |

UI T80 200 |

260 |

70 73 70 |

5.6 4.9 3.8 |

475 |

845 |

|

12Sh - 9 300558 |

576 792 972 |

160 220 270 |

6õ 58 50 |

1450 |

127.5 150 16ï.5 |

180 |

80 83.5 79 |

4.5 |

435 |

5ï2 |

|

12Sh - 9A 300S58A |

530 720 893 |

147 200 248 |

55 49 42 |

1450 |

99.2 116 131 |

155 |

80 83 78 |

4.5 |

402 |

572 |

|

12Sh - 9B 300S58B |

504 684 835 |

140 T90 232 |

4"2 43 37 |

1450 |

82.5 97.T 108 |

13ã |

79 82 78 |

4.5 |

378 |

572 |

|

12Sh - 13 300532 |

612 792 900 |

170 220 250 |

38 32.2 25.5 |

1450 |

76.2 80.3 78. 1 |

90 |

83 86.5 80. I |

4.5 |

352 |

809 |

|

l2Sh - 13A 300S32A |

550 720 810 |

153 200 225 |

3i 26 20.5 |

1450 |

š8.l 60.7 58 |

75 |

80 84 78 |

4.5 |

322 |

809 |

|

12Sh - 19 300S19 |

6t2 ï92 935 |

170 220 260 |

23 19.4 14 |

t450 |

47.9 51 47.6 |

55 |

80 82 75 |

4.5 |

290 |

660 |

|

12Sh - l9A 300S19A |

504 720 900 |

140 200 250 |

20 16 11.5 |

1450 |

34.8 38.3 37.6 |

45 |

79 82 75 |

4.5 |

262 |

660 |

|

12Sh - 28 300512 |

611 792 900 |

170 220 250 |

14.5 12 10 |

1450 |

30.3 32 33.1 |

37 |

80 81 74 |

4.û |

248 |

660 |

|

12Sh - 28A 3005I2A |

522 685 792 |

145 190 220 |

It.8 10 8.7 |

1450 |

22.4 23.3 24.4 |

30 |

75 80 77 |

4.5 |

225 |

660 |

|

l4Sh - 6 350S125 |

&50 1250 1663 |

236 34T 461 |

140 125 100 |

1470 |

462 545 625 |

680 |

70 78 72.5 |

3.5 |

655 |

1580 |

|

l4Sh - 6A 350S125A |

800 1180 ł570 |

223 328 436 |

125 I t2 90 |

t470 |

391 462 550 |

630 |

TO 78 70 |

3.5 |

620 |

1580 |

|

14Sh - 6B 350S125B |

745 t100 1460 |

207 305 405 |

108 96 T7 |

I4ï0 |

313 3ï3 422 |

500 |

70 77 72.5 |

3.5 |

575 |

1580 |

|

Model |

H |

n |

(kw) |

|

Hs |

|

1200 |

|||

|

14Sh - 9 350S75 |

972 1260 1440 |

270 350 400 |

80 TS 65 |

1450 |

271 314 3t9 |

400 |

78 82 80 |

3.5 |

500 |

|

|

14Sh - 9A 3S0S75A |

900 1170 1330 |

250 325 370 |

70 65 56 |

1450 |

220 247 257 |

300 |

78 84 79 |

3.5 |

465 |

t200 |

|

i4Sh - 9B 350S5B |

826 1080 t225 |

230 300 340 |

59 55 47.5 |

1450 |

178 t98 206 |

260 |

75 82 77 |

3.5 |

428 |

1200 |

|

14Sh - 13 350S44 |

972 1260 1480 |

270 350 410 |

50 43.8 37 |

1470 |

164 179 188 |

220 |

81 84 79 |

3.5 |

410 |

1105 |

|

14Sh - 13A 350S44A |

864 1120 1330 |

240 310 370 |

41 36 30 |

1470 |

121 130 136 |

180 |

80 84 8d |

3.5 |

380 |

1105 |

|

14Sh - 19 350S26 |

971 1260 1440 |

270 350 400 |

32 26 22 |

1450 |

99.7 102 95.7 |

132 |

85 88 82 |

3.5 |

350 |

880 |

|

l4Sh - 19A 350S26A |

864 1120 1296 |

240 310 360 |

26 21.5 16.5 |

1450 |

76.5 7'7 80 |

1t0 |

80 85 73 |

3.5 |

326 |

880 |

|

14Sh - 28 350516 |

9T1 1260 1440 |

270 350 400 |

20 16.2 13.4 |

1450 |

66.2 68.5 71 |

75 |

80 81 74 |

3.5 |

290 |

760 |

|

l4Sh - 28A 350S16A |

864 1044 1260 |

240 290 350 |

16 13.4 10 |

1450 |

51 48.8 49 |

55 |

74 78 70 |

3.5 |

760 |

|

|

20Sh - 6 500598 |

1450 20t6 2300 |

403 560 640 |

108 98.4 89 |

970 |

585 680 735 |

800 |

72.5 79.5 76 |

4 |

860 |

4330 |

|

20Sh - 6A 500S98A |

1349 1870 2140 |

375 520 595 |

93 85 77 |

970 |

490 564 607 |

630 |

70 77 74 |

3.6 |

800 |

4330 |

|

20Sh - 9 500559 |

1150 2016 2450 |

430 560 680 |

66 59 50 |

970 |

3t0 390 433 |

500 |

82 83 77 |

4 |

682 |

2750 |

|

20Sh - 9A 500S59A |

1405 1910 2270 |

390 530 630 |

58 50 42 |

970 |

300 34T 360 |

400 |

74 75 72 |

4 |

640 |

2750 |

|

20Sh - 9B 500S59B |

1763 |

490 |

42 |

970 |

273 |

355 |

74 |

600 |

2750 |

|

|

20Sh - 13 500535 |

1550 2016 2410 |

430 560 670 |

40 35.1 30 |

970 |

206 219 247 |

280 |

82 88 80 |

4 |

550 |

2340 |

|

20Sh - 13A 500S35A |

1870 |

520 |

31 |

970 |

186 |

240 |

85 |

4 |

510 |

2340 |

|

Model |

H |

n |

Hs |

mm |

kg |

|||||

|

20Sh - 19 500522 |

2016 2340 |

560 650 |

22 15 |

970 |

147 137 |

180 |

82 70 |

4 |

465 |

2010 |

|

20Sh - 19A 500S22A |

1296 1870 2016 |

360 520 560 |

23 17 14 |

970 |

111 108 101 |

130 |

73 80 76 |

4 |

427 |

2010 |

|

20Sh - 28 500513 |

1620 2016 2325 |

450 560 646 |

15.2 12.8 10.6 |

970 |

78.9 79 78 |

110 |

85 89 86 |

4 |

390 |

2000 |

|

24Sh-9 B00S75 |

320 |

950 |

T1 |

960 |

727 |

900 |

91 |

13 |

7d5 |

4300 |

|

24Sh - 9A 600S75A |

3168 |

880 |

6t |

960 |

585 |

710 |

90 |

2.5 |

7t0 |

4300 |

|

24Sh - 9(J) 600539 |

2700 |

750 |

39 |

730 |

319 |

380 |

90 |

4.8 |

765 |

4300 |

|

24Sh - l3 600547 |

2502 3168 3499 |

69íì 880 972 |

ô6 47.4 38 |

970 |

460 465 426 |

550 |

83 88 80 |

2.5 |

630 |

3200 |

|

24Sh - 19 600532 |

2480 3170 3960 |

700 880 1100 |

37 32 22 |

970 |

295 310 279 |

380 |

86 89 85 |

2.5 |

540 |

2áS0 |

|

24Sh - l9A fi00532A |

2304 2880 3600 |

640 800 1000 |

31.5 27 20 |

970 |

235 238 231 |

280 |

84 89 85 |

2.iì |

500 |

2550 |

|

24Sh - 8 600S22 |

2340 2880 3t20 |

650 800 950 |

23.5 2J 18 |

9'/0 |

187 195 20î |

260 |

80 84.5 81 |

2.5 |

450 |

2500 |

|

24Sh - 28A 600S22A |

2340 2880 3420 |

650 800 950 |

17.5 15.5 13 |

9'ï0 |

145 148 154 |

185 |

7ï 82 78.5 |

2.5 |

415 |

2500 |

|

32Sh - 19 800S32 |

4700 5500 6010 6460 |

t305 1530 I6î0 t795 |

35 32.5 28.9 25.4 |

730 |

5T5 580 567 567 |

630 |

78 84 83.5 80.4 |

3.5 |

740 |

5100 |

|

32Sh - 19A 800S32A |

4550 5310 5800 6250 |

t260 1475 1600 tT35 |

3t 29 26.5 23 |

730 |

492 500 496 487 |

5fi0 |

78 84 83.5 80.1 |

3.5 |

715 |

5100 |

Previous

No InformationNext

Double Suction PumpSend Inquiry